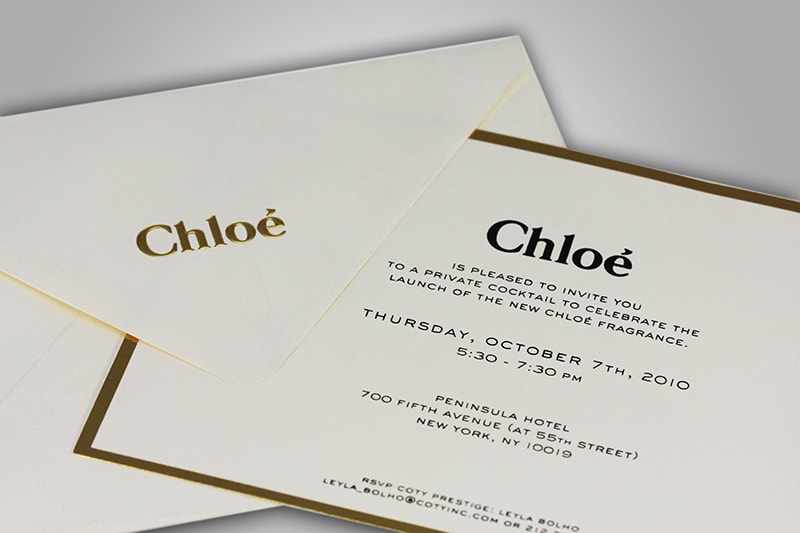

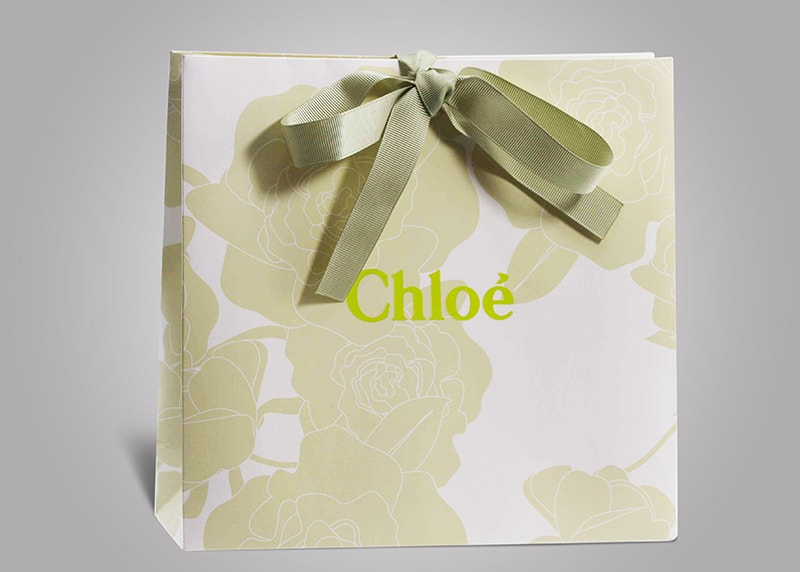

For over 21 years, PPD&G has been a leading provider of printing, packaging, display, and gift packaging services. Our full-service capabilities include engineering, prototyping, and manufacturing. Our unparalleled quality of work and reputation have allowed us to work with global brands such as Dolce & Gabbana, Nordstrom, Pepsi, Louis Vuitton, Chloe, and Christian Dior.

Print Capabilities

Our state-of-the-art machinery allows us to complete print jobs that other shops cannot. Our current capabilities include:

- Offset Printing: This type of printing yields high-quality results. The technique transfers an inked image onto a plate and then a rubber blanket, which applies the image onto the printing substrate.

- Variable Data Printing: Variable data printing is a digital printing process that can produce high volumes of printed materials. Elements can easily be changed from one copy to another, allowing for quick print times.

- Large Format Printing: True to its name, large format printing is used for large items like posters and banners. These large print jobs rely on highly specialized printers.

- Embossing: Embossing creates a raised imprint using a machine press that applies pressure to a die.

- Debossing: Debossing creates a depressed imprint. This is accomplished using a similar process as embossing.

- Heat Transfers: In heat transferring, designs are printed onto a substrate and then transferred to a material or item using heat and pressure. This is a common printing method for fabric.

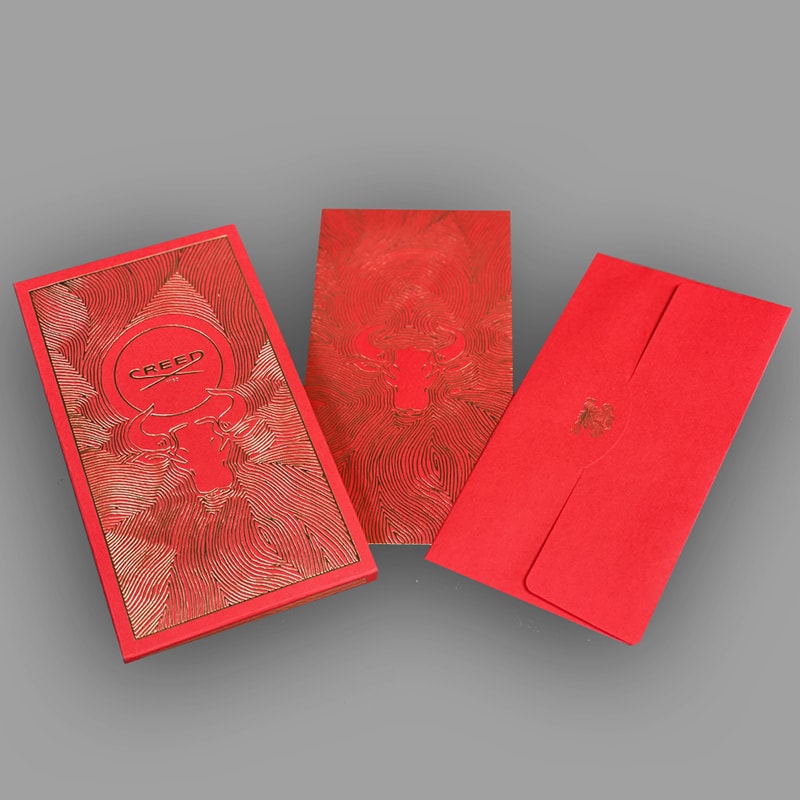

- Foil Stamping/Hot Stamping: A custom die is used in conjunction with heat and pressure to leave a metallic foil imprint of the required design.

- Sublimation Fabric Printing: Sublimation for fabric printing involves printing a design on transfer material, then applying it to the fabric medium using heat.

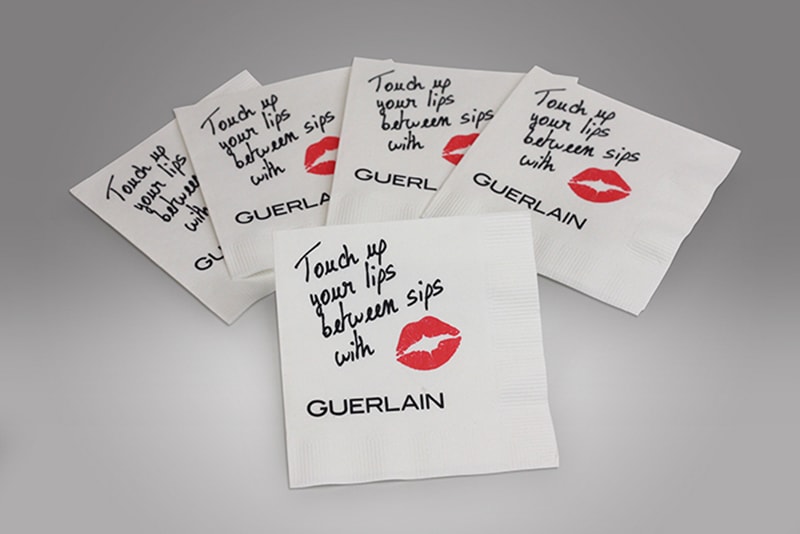

Custom-printed collateral can elevate your brand. Our printing capabilities can be used for a variety of applications and industries. Leading categories include:

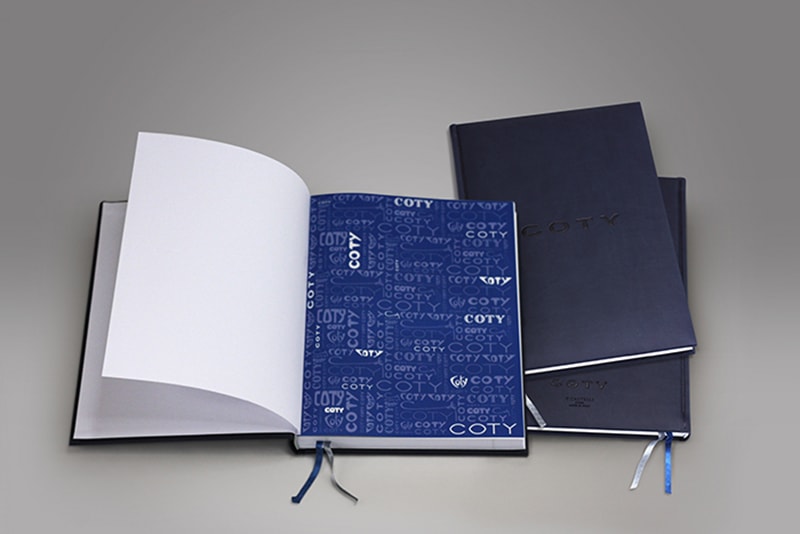

- Corporate Printing: We can meet nearly all corporate and office printing needs. We have completed numerous professional prints of business cards, letterheads, name tags, envelopes, and more.

- Custom Stationery: We design custom stationery for professional and personal communications. We use the highest quality materials to create invitations, postcards, notecards, and more.

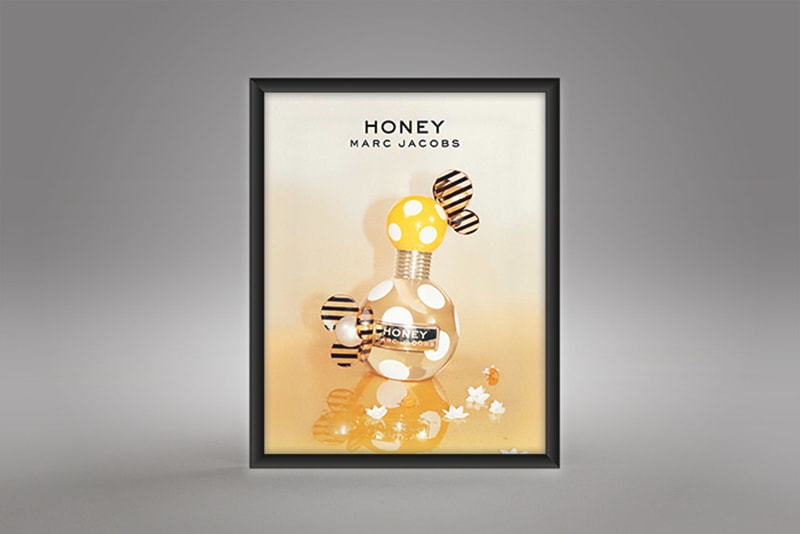

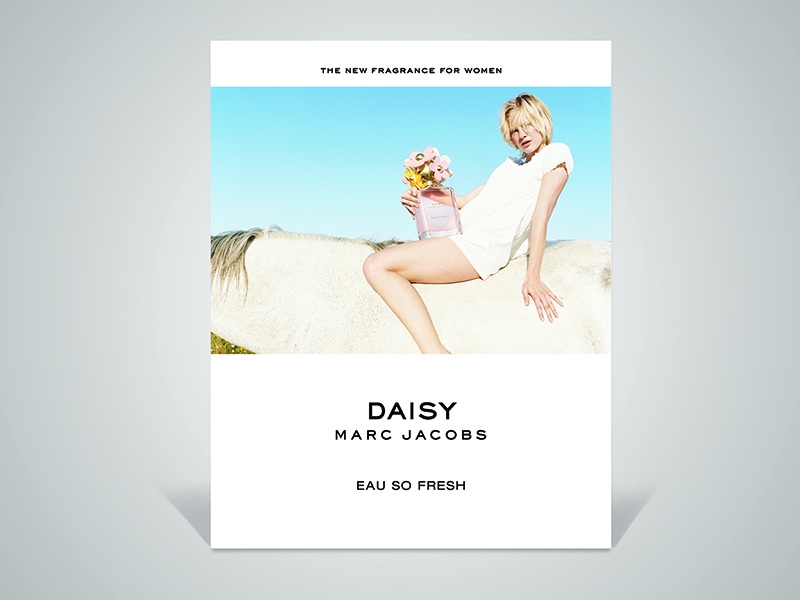

- Custom Posters: We create more than simple advertisements. Our team can design intriguing custom poster graphics that effectively deliver your brand’s message.

- Custom Hang Tags: Hang tags are effective in branding and providing information about individual products. Customers can quickly identify prices, sizes, and other important information.

- Custom Backlit Graphics: Backlit graphics are an excellent way to offer a unique promotion. Backlit posters create a focal point that attracts more attention to your product or business.

- Custom Apparel & Uniforms: Branded apparel is an excellent way to enhance brand awareness. We can easily personalize any garment to enhance your brand identity.

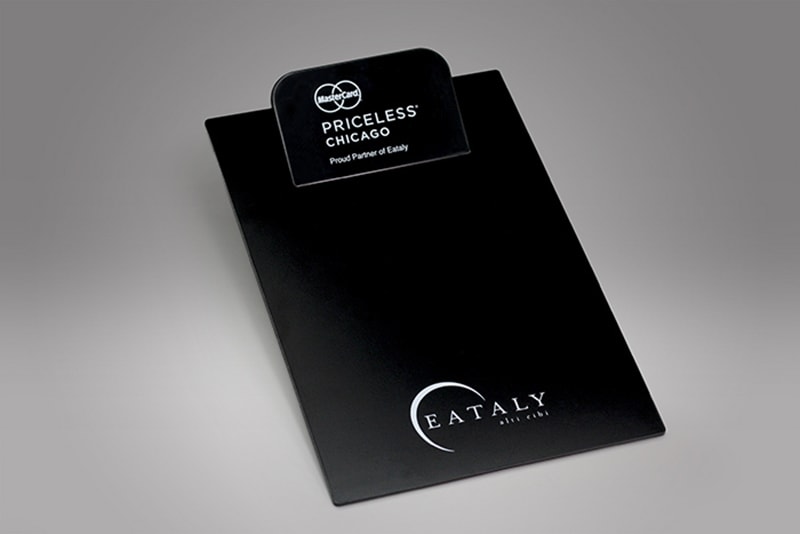

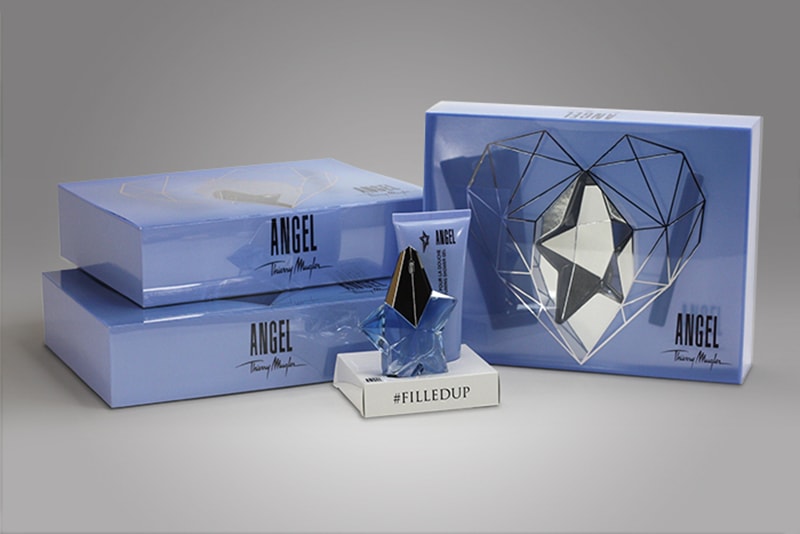

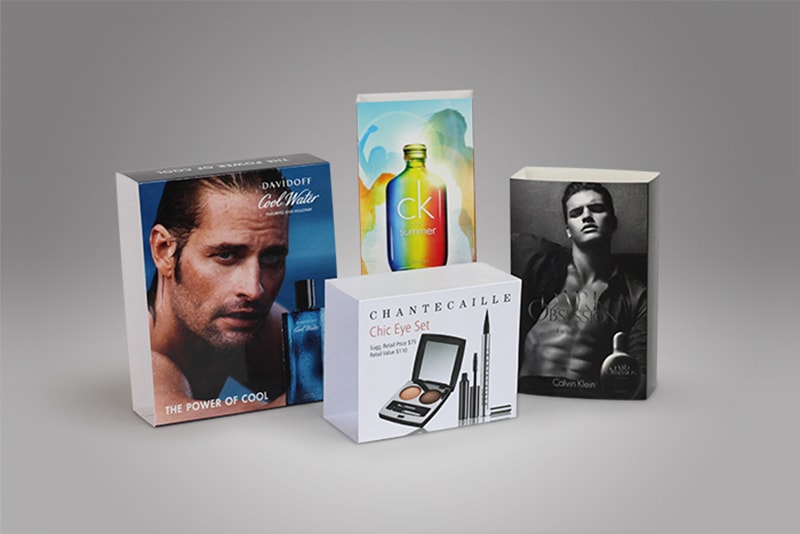

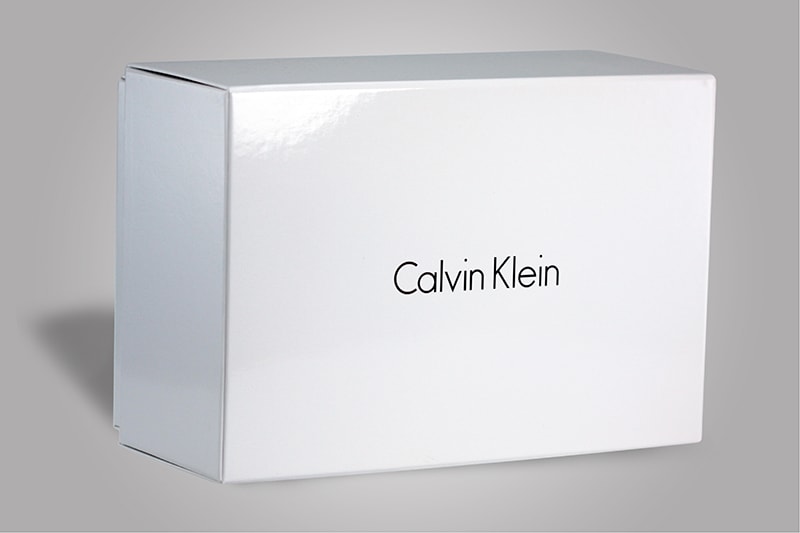

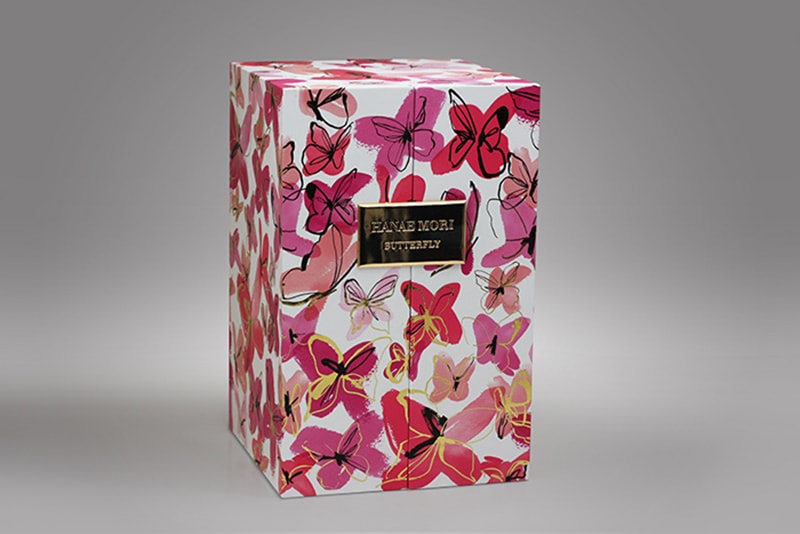

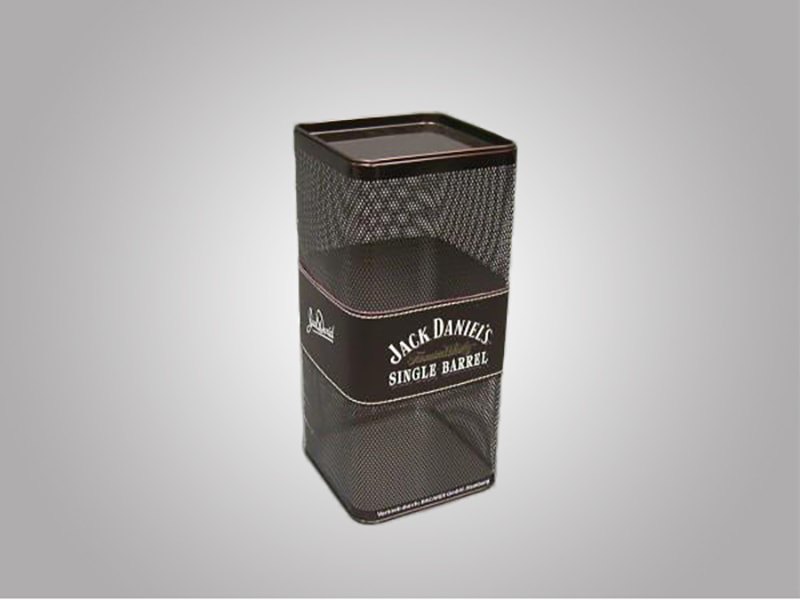

Packaging Capabilities

Visual merchandising is a fantastic way to attract attention to your products. PPD&G can provide a wide range of production and packaging options for nearly any industry. From our cutting-edge facilities, we can create brand packaging, display options, and more. Our capabilities include:

- Die Cutting: Die cutting is an efficient way to make uniform cutouts in large volumes. The process utilizes a machine and metal die that can cut items in large quantities with consistent quality.

- Mounting: Mounting secures a print to a rigid or semi-rigid object, such as a matboard, foam core, or styrene. This protects the photo or graphic from warping, wrinkling, or bulging. The mounted print can also be laminated.

- Laminating: Laminating bonds layers of materials together. This enhances the appearance, durability, and other properties of the print.

- Digital Cutting: Digital cutting is an alternative to die cutting. Instead of using a metal die, the machine can make precision cuts with the use of software, bits, lasers, and small blades.

- Fulfillment: For mail order products, a customer’s first physical interaction with your brand is the packaging. To make a good first impression, many businesses rely on high-quality, aesthetically pleasing packaging. Fulfillment can be a wide-ranging service, including sorting, collating, labeling, and shrink wrapping.

- Custom Foam Cutting: Custom foam cutting is a popular option to keep fragile goods protected during the shipping process. PPD&G only uses high-quality foams. Paired with our high-precision cutting methods, we can easily design the perfect packaging for your products.

- Vacuum/Thermoforming: This process relies on vacuuming and heating to create custom-shaped plastic material, such as trays that keep products protected in their packaging.

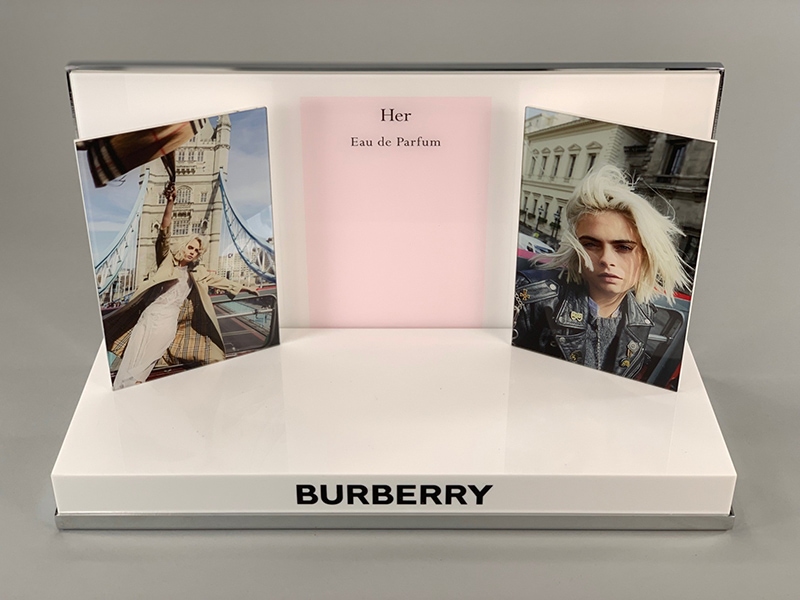

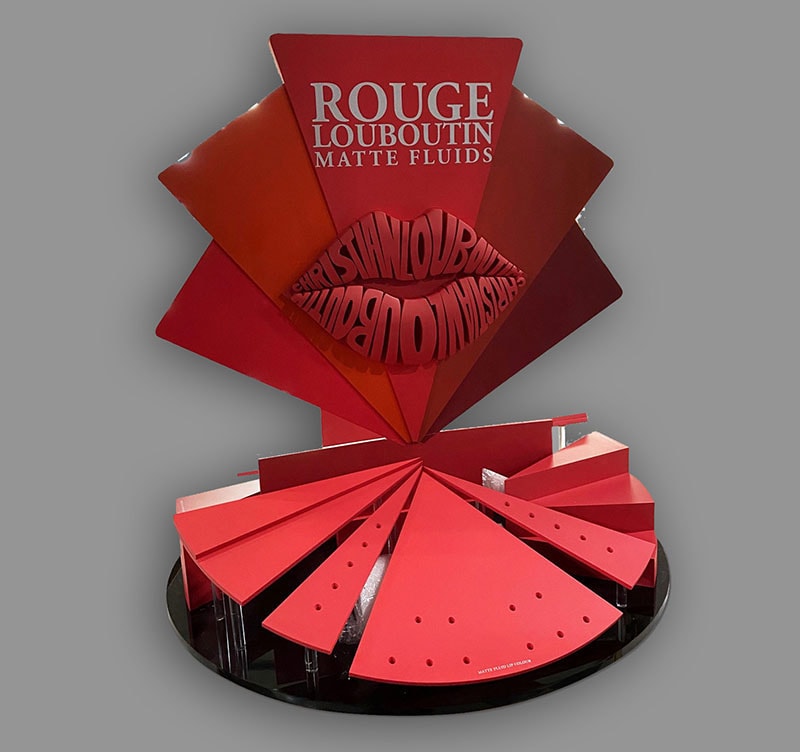

Display Capabilities

PPD&G has a wide range of capabilities when it comes to creating captivating displays. Here are the merchandising display services we offer:

- Custom Fabricating: We can work with numerous materials to create any custom fabrication need. Our experts work with wood, acrylic, foam, metal, and composite materials.

- CNC/Camera Controlled Cutting: This cutting method relies on a camera and computer to make precise cuts. Paired with state-of-the-art software, CNC camera-controlled cutting can precisely cut through a variety of materials, including glass, wood, metals, plastics, and foams.

- Heat Bending: Heat bending is a process that allows easy molding and reforming of objects. Heat is used to soften materials, allowing them to be bent into the desired shape.

- First & Second Surface Mounting: Mounting secures a designed graphic or picture to either a rigid or semi-rigid substrate. This keeps the printed image safe from bending, warping, wrinkling, or bulging. First surface mounting is where the print is mounted to the front of the substrate, whereas second surface mounting is where the graphic is mounted to the back of a clear substrate, protecting it from the weather. The mounted object can be laminated for additional protection.

- Laser Cutting: Laser cutting provides high-quality and accurate cuts. It can be used with a variety of materials, including glass, metals, foam, and wood.

- Diamond Edge Polishing: This type of polishing is commonly used on synthetic sheet materials. It can be used on all sides to provide a polished, smooth finish.

- Flame Polishing: Flame polishing uses high heat to melt surfaces and leave a smooth finish.

- Buffing: Buffing is a technique for polishing materials. It relies on a rotary wheel to create a high shine and finish.

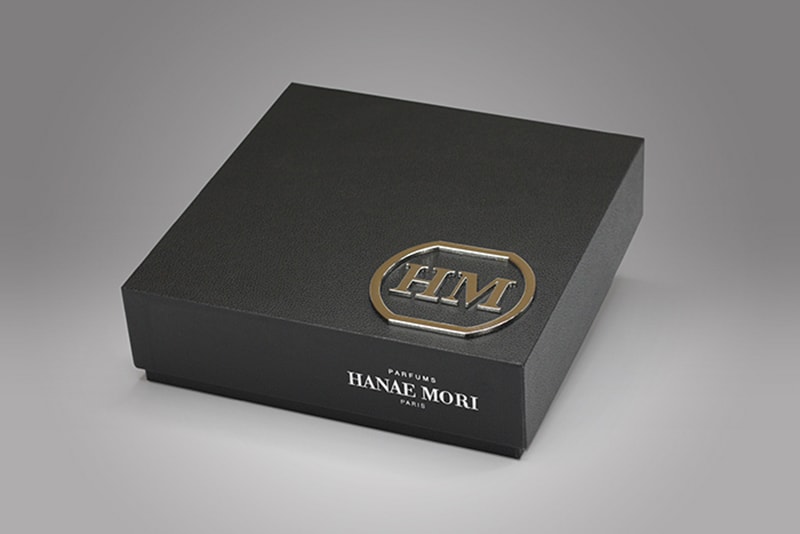

Gift Capabilities

A custom gift can go a long way in establishing a good relationship with clients, customers, and partners. Examples of gift products include tote bags, glassware, cufflinks, and cleaning cloths. PPD&G can help you create custom gifts for any occasion.

- Design: We have a dedicated team of designers to help you draft and prototype custom gifts. With our expertise in fabrication, we can help your gift look unique and memorable.

- Sourcing: While we strive to keep everything in-house, we have reliable partnerships with trusted vendors. When needed, we can help outsource certain aspects of custom gifts.

- Cut & Sew: Custom cutting and sewing can help make a gift truly unique. Our expert sewers’ attention to detail can create remarkable products from high-quality materials.

- Laser Engraving: Our laser engravers can engrave nearly any design or graphic onto metal, wood, acrylic, and glass.

- Injection Molding: Injection molding can be used to mass produce custom shapes. While plastics are commonly used with injection molding, other materials can be used based on your needs.

Choose PPD&G For Your Printing Needs

We offer a multitude of services to ensure that your print projects truly stand out. PPD&G is uniquely equipped to not only offer printing but also die imprinting, cutting, laser engraving, and more. When needed, we can take a consultative approach with clients to assist with the designing and prototype phase.

If you have any questions about our capabilities, feel free to contact us today. Already have a project in mind? Request a free quote any time.