Our varied production capabilities due to our diverse evolution give us a huge advantage in custom display solutions over our competitors both with respect to the operations we can perform in house as well as the expertise across so many product lines.

Custom Fabrication

We offer the finest quality materials in our custom fabrication processes, including, wood, acrylic, metal, foam, composites and more.

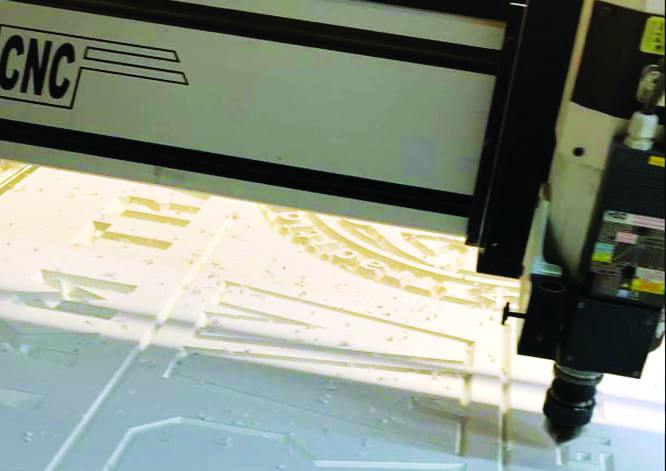

CNC/Camera Controlled Cutting

A camera-controlled cutting method, used for precision cutting of various materials, such as wood, metals, plastics, glass and foams.

Heat Bending

A process used to remold or reform objects using heat to soften a material so it can be easily formed into any desired shape.

First & Second Surface Mounting

Attaching a photograph or graphic to a backing board to protect it from bending or wrinkling.

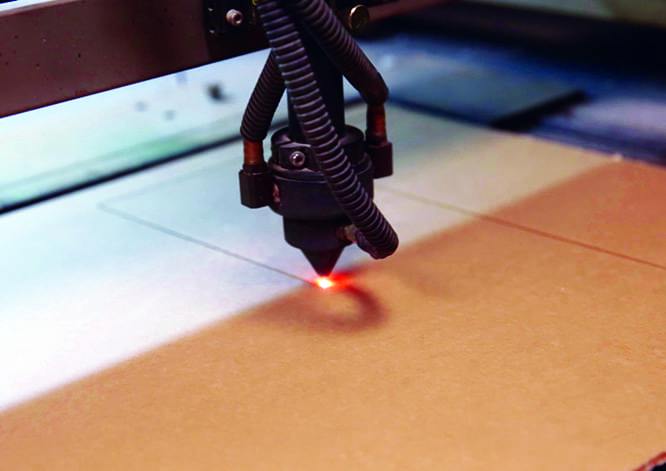

Laser Cutting

Ensures high quality and accurate cuts using a laser to cut through materials. Can be used on a variety of materials, including, wood, metals, glass, plastic, foam and more.

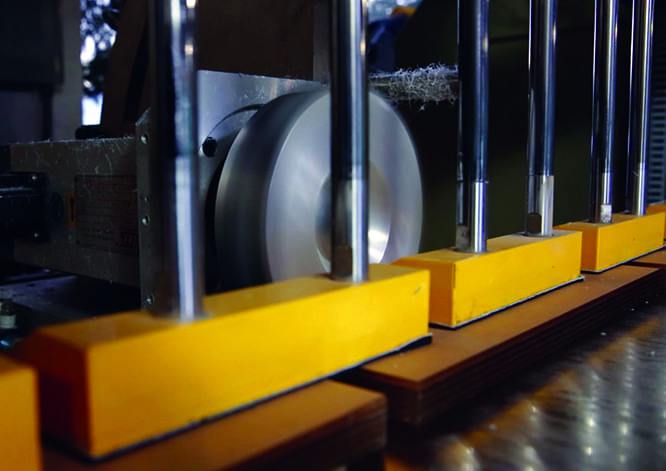

Diamond Edge Polishing

Typically used to improve the edge of synthetic sheeted materials, transforming to a pristine finished surface on all sides.

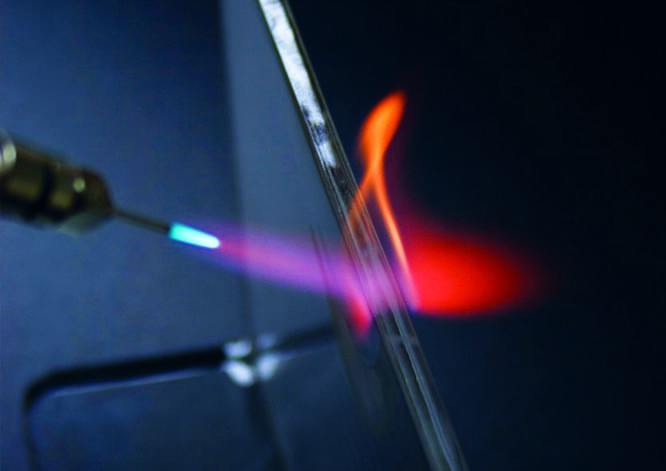

Flame Polishing

Process of exposing materials to a flame or heat to melt the surface and smooth it out.

Buffing

Utilizing a rotary wheel to polish materials to a museum quality high shine finish.

Custom Fabrication of Merchandising Displays

At PPD&G, we combine premium materials with expert design techniques to create customer-oriented display solutions for a range of marketing and branding applications. Working with wood, acrylic, metal, foam, composites, and more, our skilled professionals fabricate unique and impactful displays in the following categories:

- Video/LED displays

- Visual merchandising displays

- Retail displays

- Point of purchase (POP) displays

- Printed fabrics

- Window decorations

- Custom hanging displays

Learn more about our custom fabrication capabilities and how they can serve your custom display project needs.

CNC/Camera-Controlled Cutting

With computer numerical control (CNC)/camera-controlled cutting, pre-programmed software and code precisely guide the movement of the cutting tools while an onboard camera assists with alignment and process monitoring. Benefits of this cutting technique in POP display manufacturing include:

- Exceptional accuracy and efficiency for complex, fine cuts

- High repeatability and consistency in patterns across multiple displays

- Compatible with expanded PVC, styrene, acrylic, wood, and more

CNC/camera-controlled cutting is often used for POP displays with:

- Complex geometric shapes

- Cutouts and pockets containing products

- Letters for signs

- Knockdown assemblies

Heat Bending

The heat bending process permanently bends or re-molds flat thermoplastics and other materials by using heat to temporarily increase their malleability. For example, hot-wire bending—also known as line bending or strip heating—uses a concentrated line of heat to bend a specific area of the material. The suitability of heat bending for an application depends on the complexity of the desired bend as well as the type and thickness of the material being used.

In fabricating marketing displays, hot-wire bending and other heat bending techniques are useful for:

- Creating specific angles or curves in flat material

- Bending a sheet of material in half

- Reshaping materials without additional tooling/hardware

Advantages of heat bending include:

- Fast and affordable

- Causes minimal distortion or compositional damage

- Requires minimal tooling

- Compatible with most thermoplastics

Depending on the application, potential disadvantages include:

- Limited to simple bending

- Compatible material thickness is limited

- Not suitable for every material

First & Second Surface Mounting

Surface mounting prevents the bending or wrinkling of graphics by attaching them to a supportive substrate. Options include:

- First surface mounting: The graphic is mounted on the front, or viewing side, of the substrate.

- Second surface mounting: The graphic is mounted on the back of a clear substrate, allowing it to be protected from weather and other elements.

Laser Cutting

Laser cutting equipment uses a focused laser beam to accurately cut metals, plastics, glass, wood, and foam. The precision of this technique makes it ideal for creating smooth, polished POP displays and other high-quality signage for a range of retail and marketing environments. Benefits of laser cutting include:

- High dimensional accuracy

- Minimal distortion or warping

- Can create highly complex shapes with high precision

- Wide range of material options

Diamond Edge Polishing

Diamond edge polishing uses a rotating diamond cutter to polish the edges of acrylic sheets and other synthetic materials. This technique is ideal for creating sophisticated marketing displays with flawless surface finishes on all sides. Edge finishes include matte and slightly polished. Benefits include:

- High levels of clarity

- Exceptional consistency

Flame Polishing

Commonly used with plastic or glass, flame polishing uses flame or heat to melt a surface and create a smooth, polished finish. Benefits of flame polishing in marketing display fabrication include:

- Quick production

- Suitable for nearly any size or shape

- No pre-heating or pre-processing requirements

It is important to note that when a flame-polished acrylic edge, for example, is cleaned with alcohol or a chemical cleaning agent, it can cause crazing—the formation of small cracks that weaken the material’s structure. For this reason, we prefer using a different edge polishing method or recommend cleaning with gentle cleaners, water, and/or a microfiber towel. Crazing does not occur with buffing, diamond edge polishing, CNC cutting, or laser cutting.

Buffing

The buffing process uses a rotary polishing wheel to create high-shine, clear-edge finishes on a variety of surfaces. This technique can:

- Transform edges from matte to glossy

- Remove scratches, bumps, and other defects

- Create a museum-quality surface

When fabricating marketing displays, buffing is often used to achieve the pristine finishes required for use in higher-end retail and marketing environments.

Custom Display Capabilities at PPD&G

At PPD&G, our broad range of experience and flexible production capabilities allow us to create visually striking merchandising and marketing displays for nearly any application. To learn more about our display capabilities, please request a quote.