Our varied production capabilities due to our diverse evolution gives us a huge competitive edge over our competitors both with respect to the operations we can perform in house as well as the expertise across so many product lines.

Cut & Sew

With tremendous attention to detail and using the finest quality materials we ensure the best for a custom cut and sew project.

Design

Our experienced designers are backed by our expertise in fabrication, allowing us to flawlessly bring your design vision to life.

Laser Engraving

Process of using lasers to etch a design or graphic onto various materials including, but not limited to, metal, wood, acrylic, and glass.

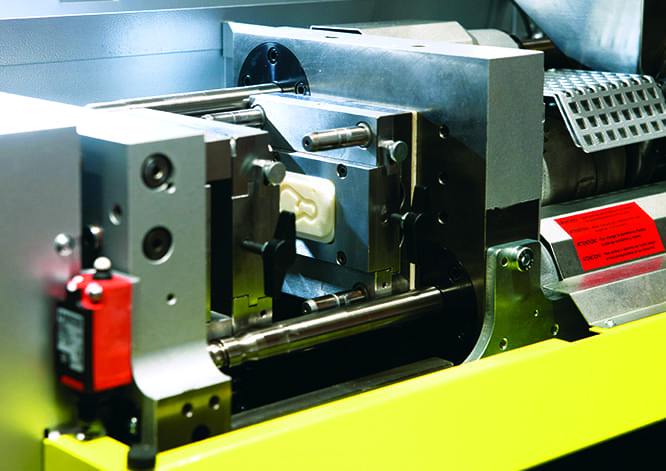

Injection Molding

Process used to produce parts by injecting materials, commonly plastics, into a mold to form completely custom shapes and objects.

Sourcing

Producing within our own facilities remains our #1 option, but if required, we have established relationships in China, giving us the option to produce within our facilities or outsource to China with a high degree of control and oversight.

For over 20 years, PPD&G has been a leading provider of printing, packaging, display, and gift services. We have expanded our capabilities by acquiring state-of-the-art equipment, adopting modern methodologies, and hiring a highly experienced team with backgrounds in design, engineering, technical, and customer care fields. Our in-house capabilities give us a significant competitive edge over our competitors across numerous product lines.

At PPD&G, we can include a gift with purchase or for any other occasion. In addition to being a great marketing strategy, custom gifts help boost your relationship with your customers. Our team uses a wide range of processes to produce the perfect gift, such as:

- Cut and sew

- Designing

- Laser engraving

- Injection molding

- Sourcing

Our gifts with purchase (GWP) are made from wood, acrylic, glass, and/or plastic materials, and examples include tote bags, cuff links, cleaning cloths, mirrors, and glassware. Read on to learn more about our gift capabilities.

Cut and Sew

One of the ways to make a gift look exceptional and unique is through a cut and sew process, where materials are printed before being sewn together. It is often used to manufacture custom garments, stuffed animals, curtains, and rugs.

Cut and sew services require attention to detail to create a product that perfectly meets the customer’s demands or designer’s vision. Our experienced team uses high-quality materials to create high-quality gifts. We can also accommodate low quantities and limited production runs.

Design

Our designers are also highly skilled in fabrication, which helps them create beautiful designs following customer specifications. Our custom fabrication expertise and capabilities can turn various raw materials like foam, metal, composites, wood, and acrylic into unique final products. Custom designs help GWPs stand out and make a memorable impression on customers.

Laser Engraving

At PPD&G, we perform laser engraving services to make high-quality custom gifts. Laser engraving involves vaporizing materials using a focused laser beam, resulting in precise marks that can be seen and touched. Laser engraving can be done on multiple materials, including:

- Glass

- Metal

- Wood

- Acrylic

Because it uses computer-guided technology, laser engraving is highly precise and accurate even for complex shapes. It is a preferred process because of its aesthetically appealing and repeatable results. Laser engraving can produce logos, barcodes, QR codes, serial numbers, and custom designs.

Injection Molding

Injection molding services enable PPD&G to produce high-volume, intricate parts from raw plastic materials. In injection molding, plastic pellets are melted and forced into a closed mold to form custom shapes and objects.

One of the main benefits of injection molding is flexibility—it’s ideal for various colors and complex geometries with tight tolerances. Injection molding is compatible with numerous materials, including thermoplastics, thermosets, and silicone. The process is also highly repeatable, so you can quickly and reliably create high volumes of identical gifts.

Sourcing

While we aim to produce everything in-house, we also maintain partnerships with reputable and trusted vendors overseas. Flexible sourcing services help us scale to meet ever-changing market conditions. For example, outsourcing to our trusted partners in China allows us to expand, oversee, and control our production as needed.

Partner With PPD&G for Custom Gifts and More

At PPD&G, our varied production capabilities and unmatched quality of work have enabled us to become a leading provider of printing, packaging, display, and gift manufacturing services. Our experienced staff and cutting-edge machinery allow us to engineer, prototype, and manufacture custom gifts to exact specifications.

Request a quote or get in touch today to learn more about our capabilities.