Our varied production capabilities due to our diverse evolution gives us a huge custom packaging solutions edge over our competitors both with respect to the operations we can perform in house as well as the expertise across so many product lines.

Die Cutting

Die cutting is a process that requires a machine and a metal shaped object with a raised area for cutting, called a die, to mass produce cut items uniformly.

Mounting

Attaching a photograph or graphic to a backing board to protect it from bending or wrinkling.

Laminating

Bonding layers of material together to enhance durability, appearance, and/or other properties.

Digital Cutting

Precision cutting without the use of a die, that utilizes software in combination with lasers, bits, and small blades to cut through materials.

Fulfillment

The process of receiving goods or orders, then processing and delivering orders to customers. To us this can mean a plethora of things, including services like sorting, labelling, collating, shrink wrapping, and more.

Custom Foam Cutting

We source high quality foam, and utilize various cutting methods to ensure a perfect fit for your packaging.

Vacuum Thermoforming

Vacuum thermoforming is a process that uses heating and vacuuming to form plastic into custom shaped materials, we typically utilize in making trays that protect products within packaging.

Packaging Solutions and Capabilities

At PDD&G, we offer a wide range of production and packaging services to meet the unique needs of different products and markets. To serve our growing markets, we have always operated with a spirit of innovation. With our state-of-the-art production and packaging equipment and a team that holds over 96 years of manufacturing experience, we have the knowledge and resources to produce superior-quality packaging solutions while optimizing our processes and methodologies to drive continuous growth. Through our world-class design services and complete project management system, we offer brand packaging, visual merchandising, and display options, and we are continually evolving our product lines to offer custom-curated packaging solutions for our customers across industries.

Die Cutting

Die cutting is a fast and precise cutting process that produces high-volume orders of identical goods and shapes. A custom-shaped metal die cuts precise shapes through materials like paper, cork, cardstock, cardboard, rubber, etc. to produce uniform designs with crisp edges. Die cutting is an effective way to create visual intrigue in your printed products to drive customer engagement. We offer a wide selection of standard and custom die options so our clients can include custom packaging inserts such as:

- Instruction cards

- Thank you cards

- Discount offers

Mounting

Visuals are crucial for appealing to customers in every commercial environment. Our displays and packaging products include mounting options so our clients can feature photographs, images, and other graphics on a stable backing board. This technique strengthens displays for longer-lasting use without the graphics bending or wrinkling over time. We can mount virtually any two flat materials together provided the material is less than 1” thick.

Laminating

Paper-based displays are a popular choice for packaging worldwide, point-of-sale displays, end cap displays, and other visual merchandising setups. However, unprotected paper and cardboard objects can degrade in humid, wet, or high-touch environments. Our lamination services are designed to encase display materials in a light layer of protective plastic. In the lamination process, layers of plastic bond together, holding objects between the two layers to seal away moisture. Not only does it provide extra durability and rigidity, but the glossy appearance of the lamination can enhance the appeal of the visual display. We recommend laminating displays that are going to be in humid environments, areas where the displays can become dirty quickly, or for high-contact materials, such as menus.

Digital Cutting

Digital cutting services are designed to give more freedom for innovative, unique designs, especially on low-volume orders or oversized cut-outs. Digital cutting tools can move across a larger area to make cuts, allowing for a greater range of designs and options across a large installation. Rather than using a die, this cutting method uses a combination of software and cutting tools to create precise, unique designs. Digital cutting software can translate a digital design file into instructions that automated or robotic cutting tools then execute. Digital cutting can be done with sharp mechanical blades, bits, or lasers, based on the type of material and the intricacy of the design.

Fulfillment

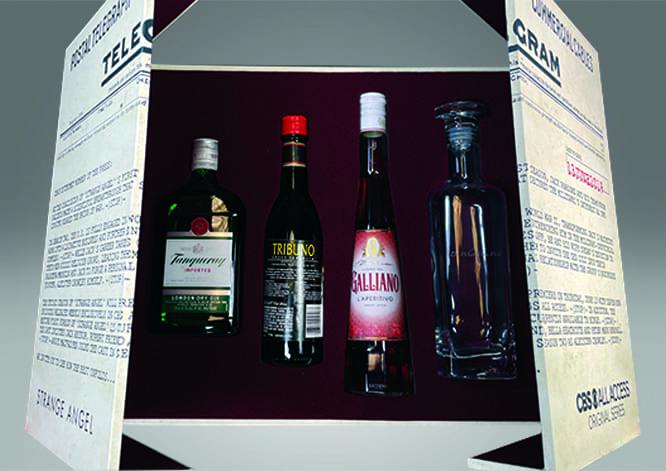

Simplify your supply chain concerns with complete in-house fulfillment. At PDD&G, we can manage all of the in-between steps to ensure your packaging and displays are created and routed to the right place the right way. We can create custom-tailored influencer boxes with internal platforms to house various products. Our fulfillment services include:

- Order processing

- Sorting

- Delivery

- Collating

- Labeling

- Shrink Wrapping

Custom Foam Cutting

Foam inserts can protect fragile goods throughout the transportation, storage, and delivery process. We use high-quality foams that are formulated to secure breakable goods without damaging them. We utilize our in-house cutting tools and equipment to create custom inserts that are precisely shaped to fill gaps in packaging, hold goods in specially designed cavities, and otherwise reduce jostling and breakage. Our team can create standard inserts or custom foam inserts that perfectly fit complex packaging needs. Our custom foam cutting services also include waterjet, die cut and laser foam cutting for displays.

Vacuum Thermoforming

As a custom box manufacturer, we can add 3D inserts to your packaging for even more stability and reliability. We offer vacuum thermoforming services — a precision manufacturing process that uses a combination of heat and vacuuming power to create custom-shaped plastic inserts, trays, and supports. Our trays are precisely shaped to the contours of our clients’ products for product protection, appealing packaging, and a satisfying customer experience upon delivery.

Custom Packaging Solutions at PDD&G

At PDD&G, we offer a complete suite of packaging solutions through our in-house manufacturing, machining, and logistics capabilities. Contact us today to learn more about how to optimize your product packaging with better supports and inserts, or request a quote to start your high-end packaging order.